KEL’s Rectangular Flotation Unit

MRLP – DAF with Lamella Plates

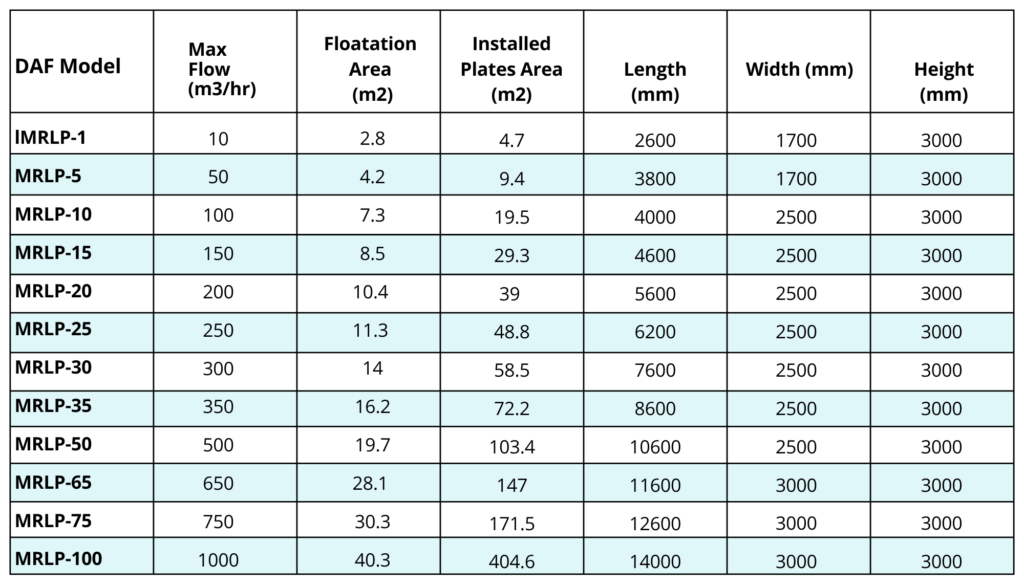

The application of Dissolved Air Flotation (DAF) is to separate solids from liquids with the help of air bubbles. Our DAF units consist of a flotation tank and air dissolving system. With the ADT (Air Dissolving Tube) we are able to produce very stable microbubbles that attach the light impurities from raw water and bring them on the water surface in the flotation tank, forming a very consistent sludge blanket. The floated sludge blanket is then removed from the top with the scraper and extracted with the paddle wheel to the sludge tank. The clarified water is collected in the central part of the flotation unit. The heavier sedimented sludge is drained out from the unit by an automatic purge system.

MR-DAF with lamella plates (LP) is especially designed for very high hydraulic capacity in smaller surface areas, up to 1000 m3/h and for higher concentration of suspended solids, with excellent removal rates. The sludge scraping and removal system is very durable and efficient.

We are dedicated to providing the best solutions for your waste water treatment

MR-DAF with lamella plates (LP) is especially designed for very high hydraulic capacity in smaller surface areas, up to 1000 m3/h and for higher concentration of suspended solids, with excellent removal rates. The sludge scraping and removal system is very durable and efficient.

We are dedicated

to providing the

best solutions for

your waste water

treatment

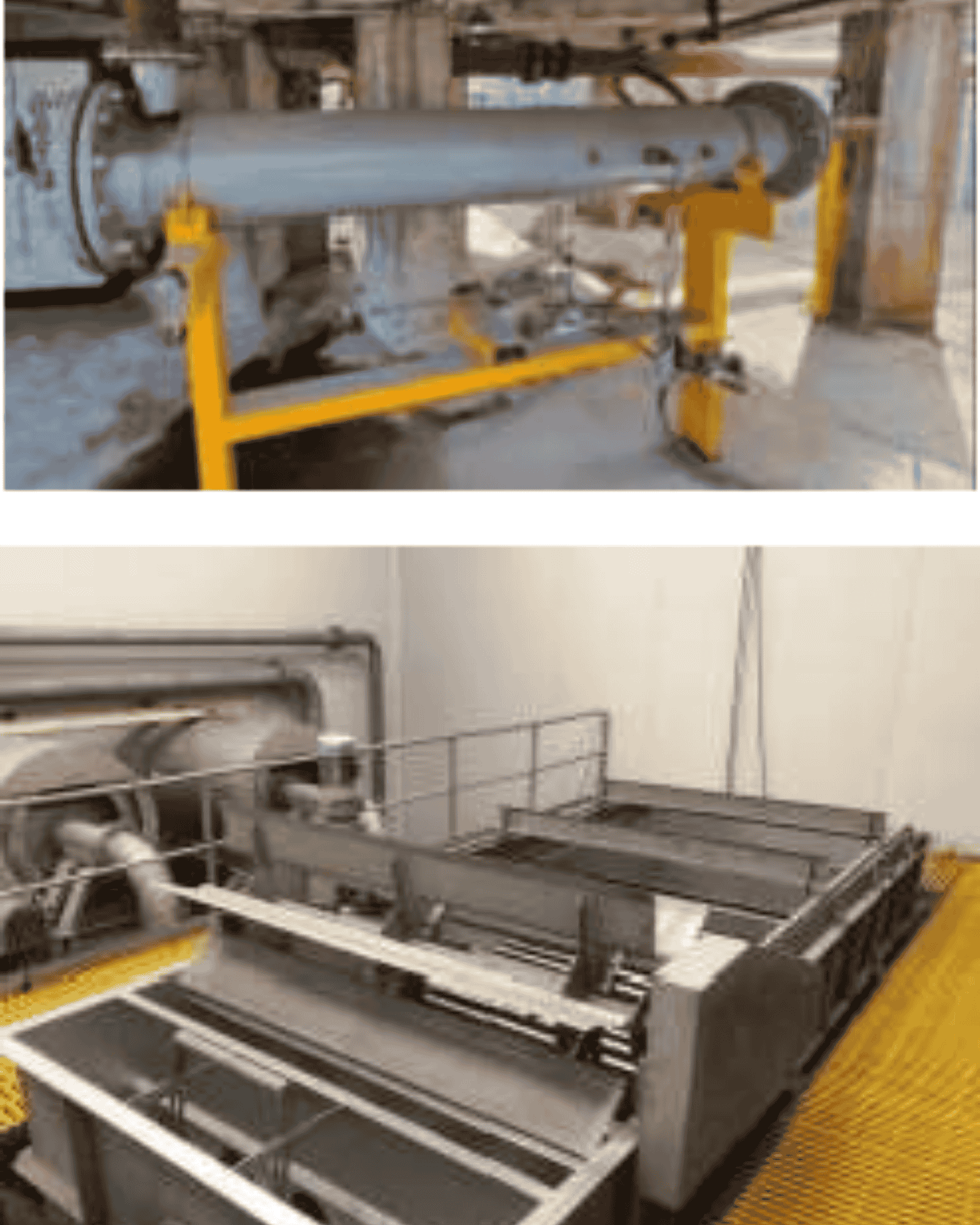

Our ADT

The KEL Air Dissolving Tube (ADT) is used to saturate air into recycled treated water. At atmospheric pressure, this creates millions of micro bubbles in the range of 30–50 microns.

The benefits of using our flotation units with our ADT:

- Entire process of air saturation takes only approximately 8-12 seconds

- KEL ADT has a small footprint and easy O&M

- Micro bubbles lead to very high solids removal efficiency

- Other saturation systems may fail in the presence of TSS > 2000 mg/L

Advantages

- Smaller footprint, fully metallic structure with minimum or no civil works required

- Higher capacity product, can handle high flow rates in a single unit

- Low operation cost, low power requirement and minimal manpower intervention

- Simple installation, operation and maintenance

- Excellent removal efficiency for heavy loads of suspended solids and oil

Applications

- Pulp and paper industry

- Desalination plants

- Powerplants Oil and gas

- industries Colour removal

- DAF as a secondary clarifier

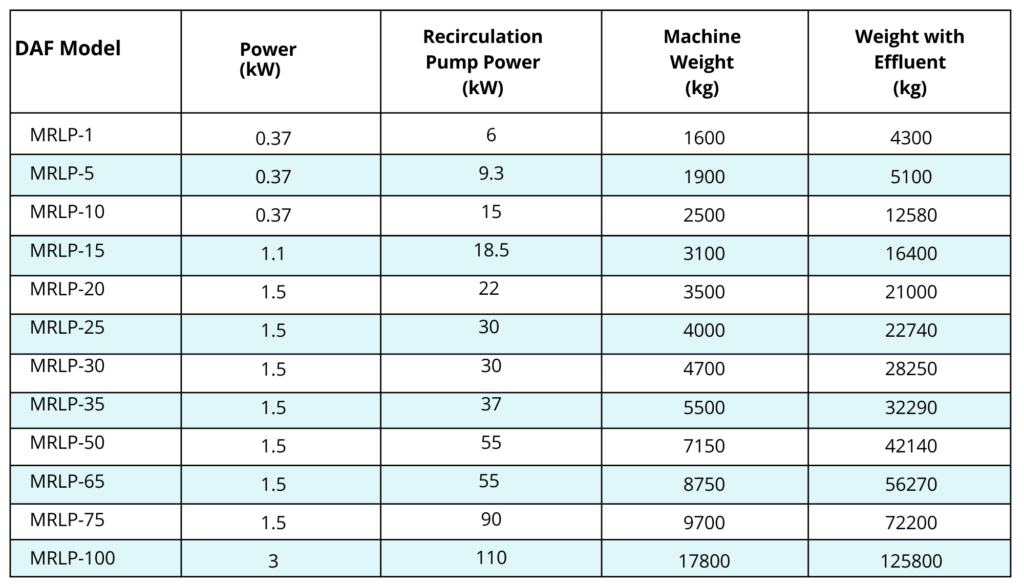

Technical Details

Flow and dimensioning details

Power requirements and weight details

Max Flow considers 30% recycle flow This data is true for cases where solids loading is maximum 2000 mg/L *Weights data is approximate

Subject to proper chemical dosing, operation and maintenance as mentioned by KEL Environmental Engineering d.o.o.