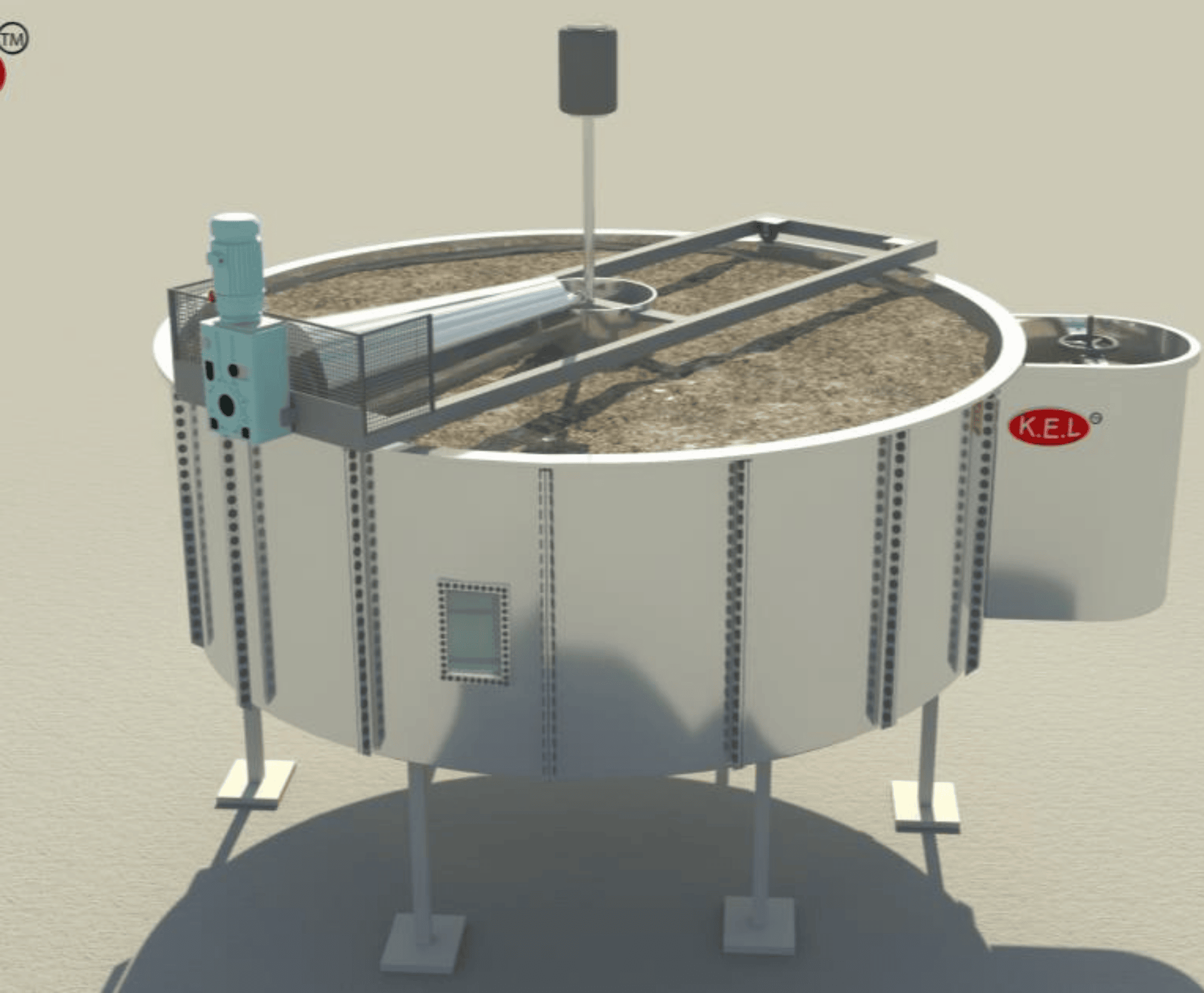

KEL’s Circular Flotation Unit

MC – DAF

The application of Dissolved Air Flotation (DAF) is to separate solids from liquids with the help of air bubbles. Our DAF units consist of a flotation tank and air dissolving system. With the ADT (Air Dissolving Tube) we are able to produce very stable microbubbles that attach the light impurities from raw water and bring them on the water surface in the flotation tank, forming a very consistent sludge blanket. The floated sludge blanket is then removed from the top with the scoop. The clarified water is collected in the central part of the flotation unit. The heavier sedimented sludge is drained out from the unit by an automatic purge system.

KEL MC-DAFs are designed for high loadings and very efficient removal of total suspended solids, fats, oils and grease from raw water. MC units can treat a very high range of flow rates up to 700 m3/h

We are dedicated to providing the best solutions for your waste water treatment

KEL MC-DAFs are designed for high loadings and very efficient removal of total suspended solids, fats, oils and grease from raw water. MC units can treat a very high range of flow rates up to 700 m3/h

We are dedicated to providing the best solutions for your waste water treatment

Our ADT

The KEL Air Dissolving Tube (ADT) is used to saturate air into recycled treated water. At atmospheric pressure, this creates millions of micro bubbles in the range of 30–50 microns.

The benefits of using our flotation units with our ADT:

- Entire process of air saturation takes only approximately 8-12 seconds

- KEL ADT has a small footprint and easy O&M

- Micro bubbles lead to very high solids removal efficiency

- Other saturation systems may fail in the presence of TSS > 2000 mg/L

Advantages

- Compact circular unit, fully metallic structure with minimum or no civil works required

- Competitive pricing as compared to traditional circular DAFs

- 3 height options for the most efficient performance based on the application and parameters

- Simple installation, operation and maintenance

- Excellent efficiency for suspended solids and oil removal

Applications

- Food and beverage industry

- Automobile and paint shops

- Dairy industry

- Sludge thickening

- Biomass removal

- Phosphorus removal

- Tertiary treatment

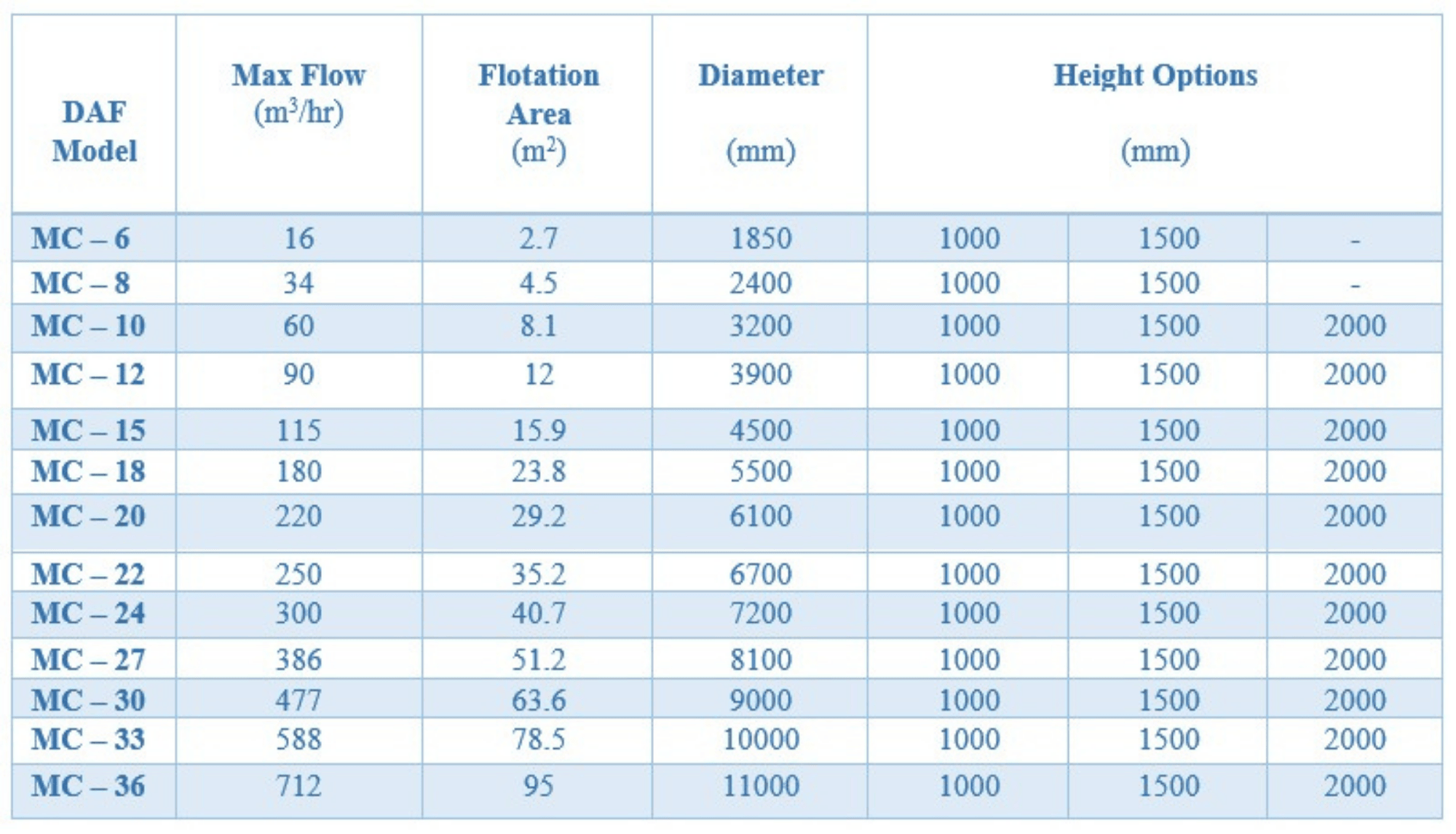

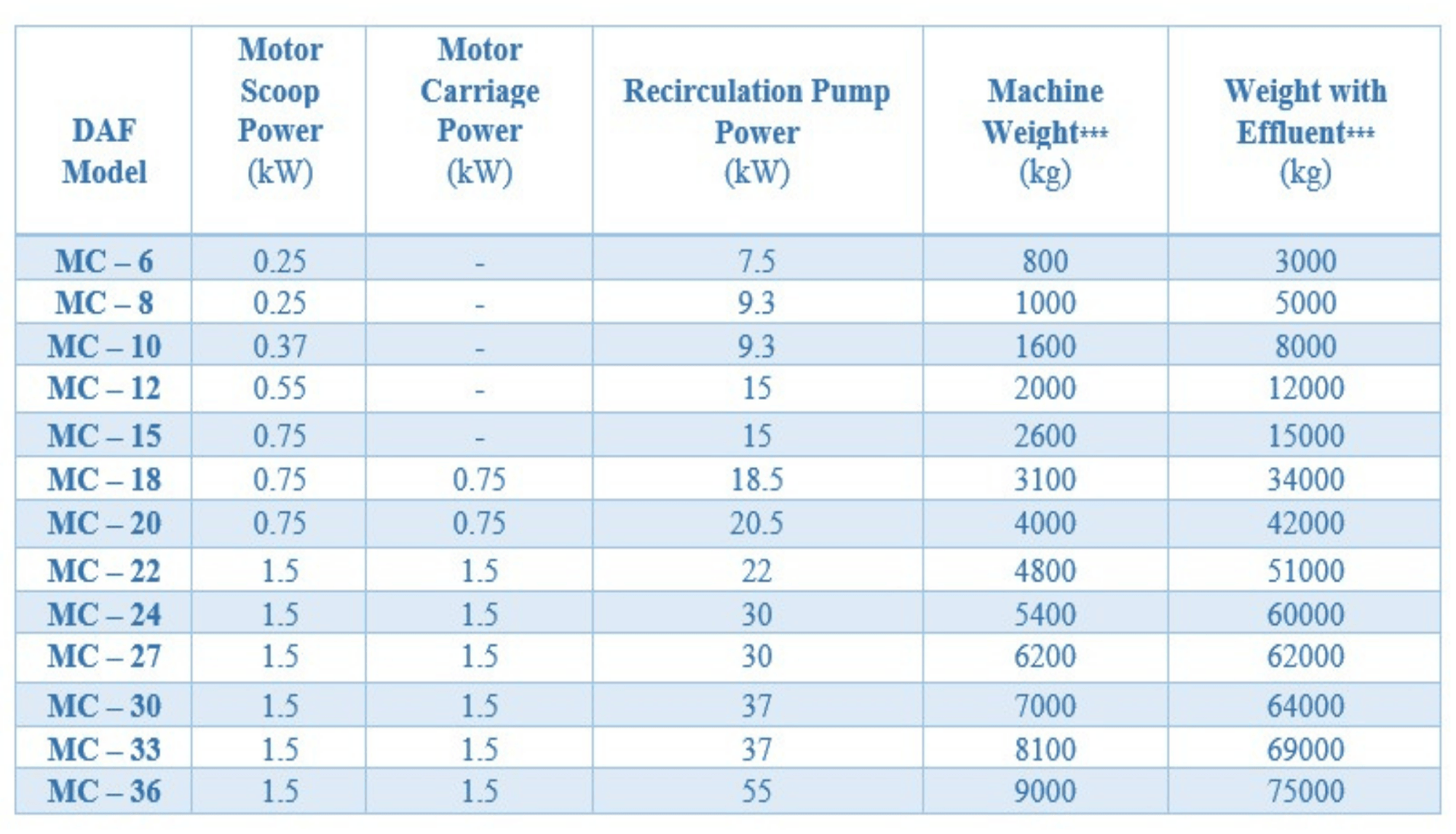

Technical Details

Flow and dimensioning details

Power requirements and weight details

Max Flow considers 25% recycle flow This data is true for cases where solids loading is maximum 2000 mg/L ***Weights data is approximate for machines with 1000 mm height

*Subject to proper chemical dosing, operation and maintenance as mentioned by KEL Environmental Engineering d.o.o.